plastic fabrication techniques are same as those used on metals, but some special attention needs to be paid to get the desired results. Mechanical equipment needs to fit for the purpose is most important.

Actually, there are no plastic CNC machines, all the machines used for cutting plastics are actually metalworking tools. Their precise rigidity and power output make them well suited for machining even hardened plastics. It can’t use woodworking machines for them are less rigid and thus produce inferior results.

How to choose the cutting tools?

Choosing the best cutting tools for plastic parts is a complex job. This is because the composition of plastics and composites can vary greatly. Some plastics are reinforced with hard carbide particles, or have additives that increase resilience, heat resistance or other properties. All these changes alter the way plastics respond to mechanical operations. Even coloring of the material is important, as color tones may change during machining, due to the high temperatures generated.

Nevertheless, it is obvious that the right cutting tool geometry must be chosen for the machining of plastic parts. For instance, milling cutters are similar to aluminum milling cutters with two flutes, but the sharp edged have a more acute angle.

The same for drills. Their main angle (120° for metals) decreases to 60°, so that the cutting chips are smaller and can be removed easier. But you cannot use this kind of drills for metals. It will break apart in minutes.

When fixturing plastic blocks, please be aware that plastics are not metals. If too much force is applied while clamping the rough part, big marks are likely to appear on the surface. Actually, if too much force is applied, the part could crack. If you want to avoid 100% leaving a mark, it is advised to use special pads made from a softer material between the fixturing device and the part.

Another concern is the rigidity of the part. For example, if you are drilling a quite large part (imagine the outer case of a laptop), you need to keep a close eye on the distance between the drilling position and the fixturing device. During this process, the drill bit will try to pull the part up along its slots, if the distance between the fixturing device is too far, the drill bit succeed, but get the part bend, or it might actually tear the part off from the fixturing device.

Cutting Parameters

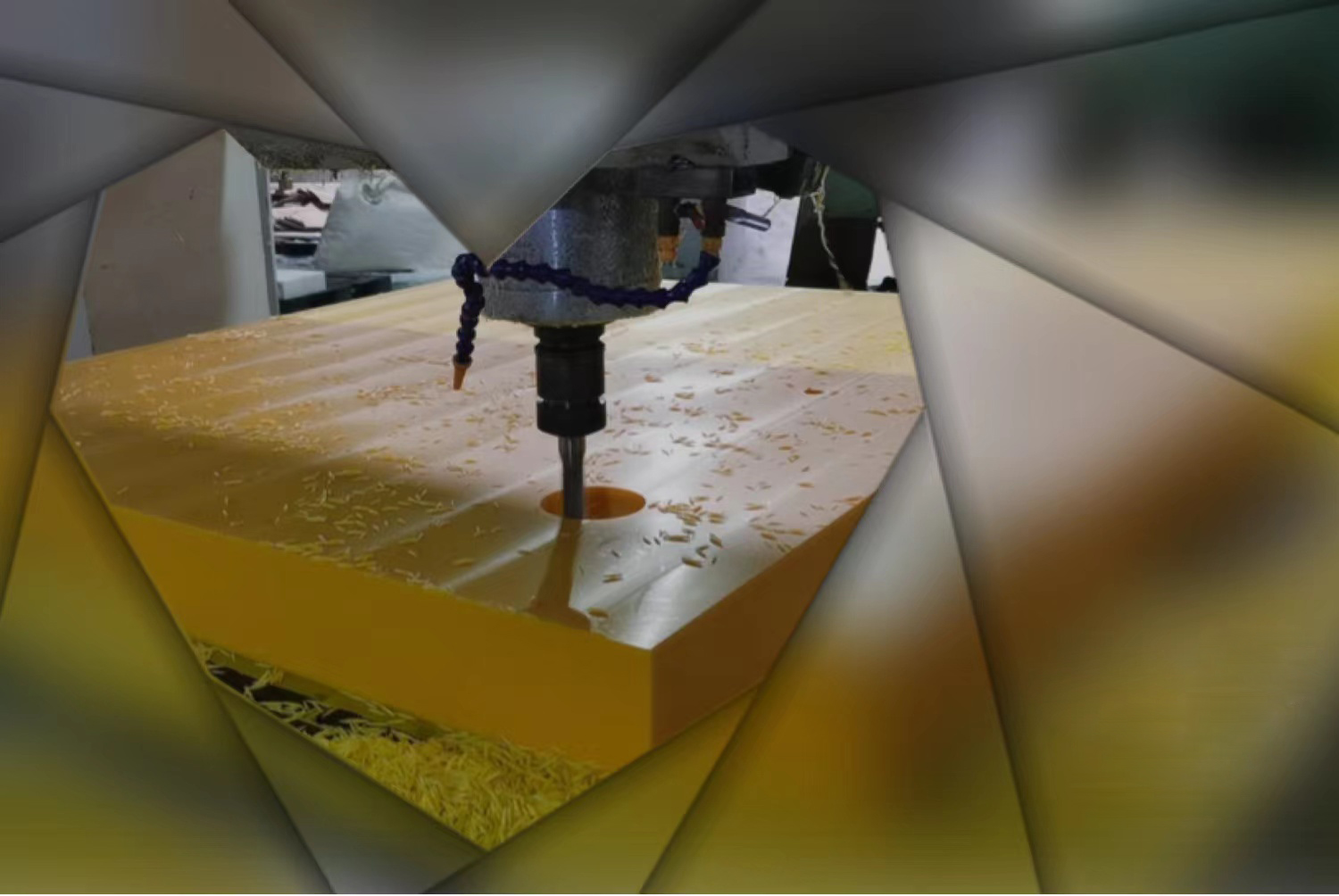

Let us take the example of CNC milling of a plastic casing to check the plastic cutting process. The main issues you need to watch out for are the excessive friction and plastic deformation of the part, not the cutting itself. To avoid the deformation issue, it should always keep the cutter sharp and if the material is not strong enough, freeze it. Plastics will become hard and brittle at low temperatures.

To prevent chips from melting onto the CNC machined parts, you need to keep the tool moving and prevent it from staying in one place for too long, removing the chips quickly. The spindle speed must also be fast when the feed speed is high. A rough estimate of the speed is about three times that of aluminum feed speed and has an appropriate cutting speed.

Let us take the example of CNC milling of a plastic casing to look at the choice of plastic cutting process. The main issues you need to watch out for are the excessive friction and plastic deformation of the part, not the cutting itself. To avoid the second issue, always keep the cutter sharp and if the material is not strong enough, freeze it. Plastics will become hard and brittle at low temperatures.

To prevent chips from melting onto the CNC machined parts, you need to keep the tool moving and prevent it from staying in one place for too long, removing the chips quickly. The spindle speed must also be fast when the feed speed is high. A rough estimate of the speed is about three times that of aluminum feed speed and has an appropriate cutting speed.

Contact: Eva Jiang

Phone: +86 189 3326 4608

Tel: +86-755-89664362

Email: sales@energetic-industry.com

Add: No.601-11, Anbo Technology Baolong Industrial Zone, Baolong 4th Road, Longgang District, Shenzhen, China