Traditionally, cnc machining has been viewed as a kind of machining method. However, modern industry is demanding ever increasing levels of accuracy of components in all possible materials. This is the reason for developing CNC Plastic Machining techniques. Nowadays, it has taken up a considerable position in high precision, small batch production and molds manufacturing of plastic parts.

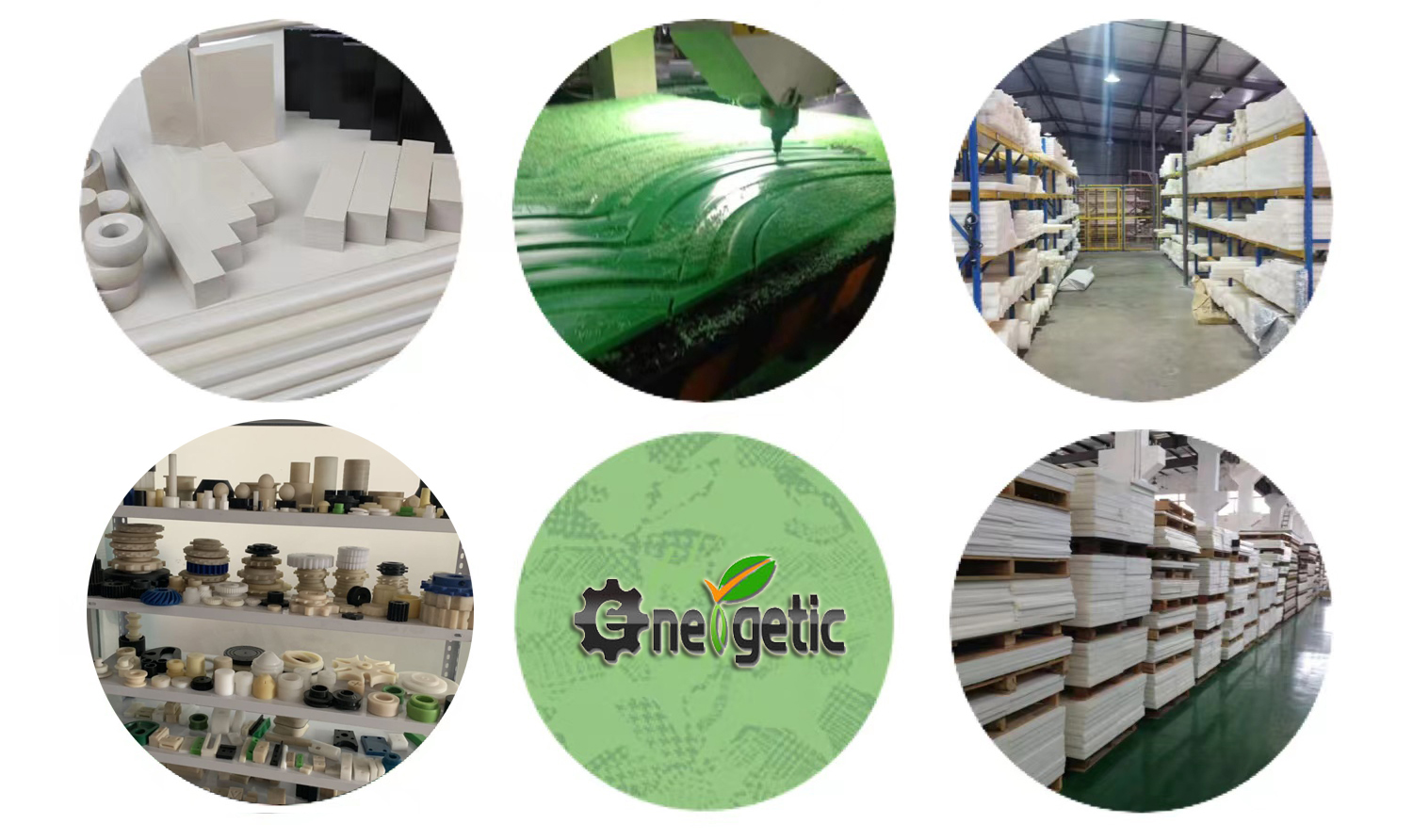

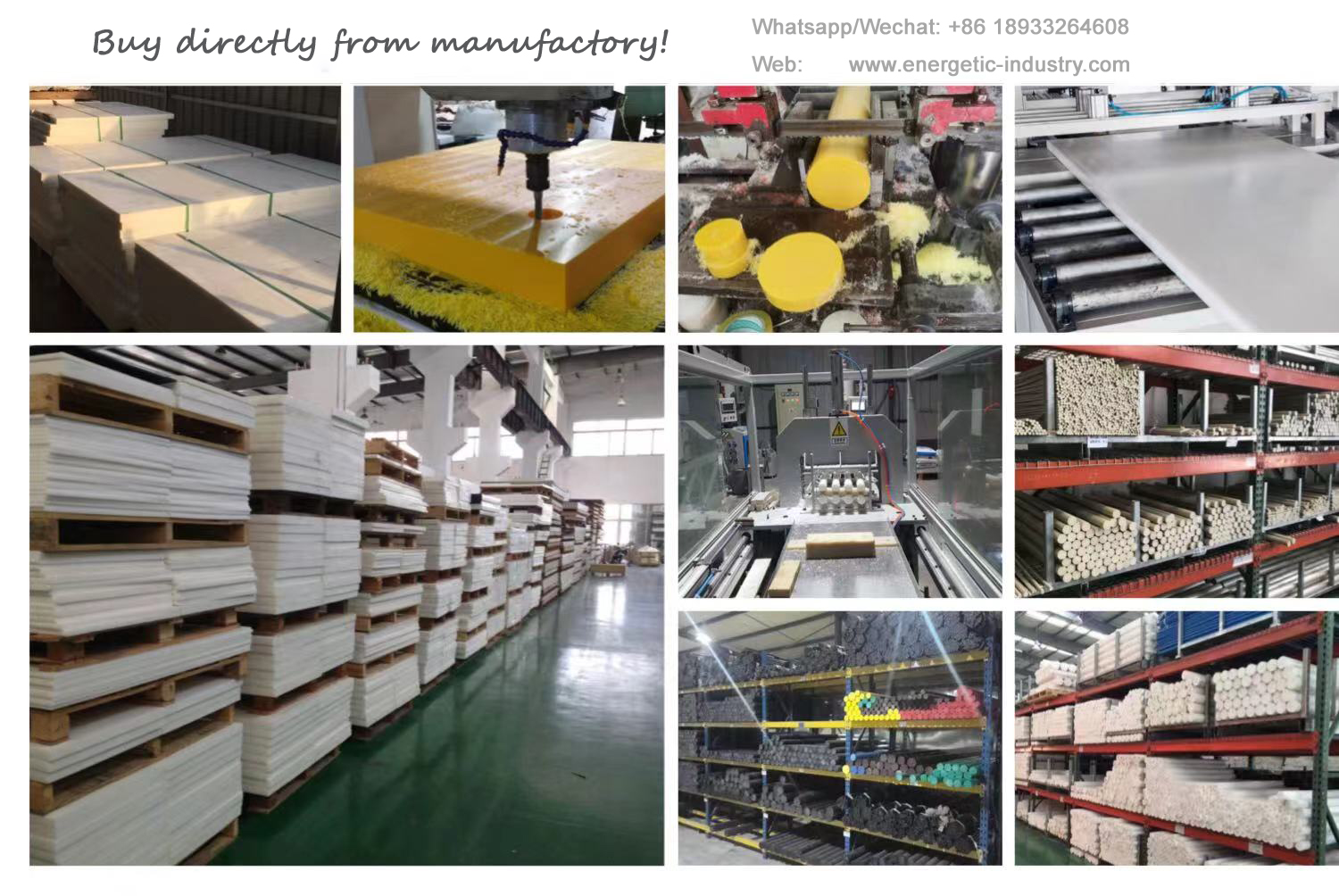

Whatever your needs are, be it a plastic mold or custom parts, combining of complex parts, or polished service in small batch production, ENERGETIC can offer advanced CNC molding services along with high temperature and high strength plastic machining materials.

Why are Plastic Parts So Popular?

The invasion of plastic in all branches of modern industry has been unstoppable ever since industrial grade polymers was invented. There are several reasons for this: plastic parts are inexpensive, lightweight and durable. Plastic parts give much lower cost of manufacturing them compared to metal parts.

Advantage of CNC Machined Plastic Parts

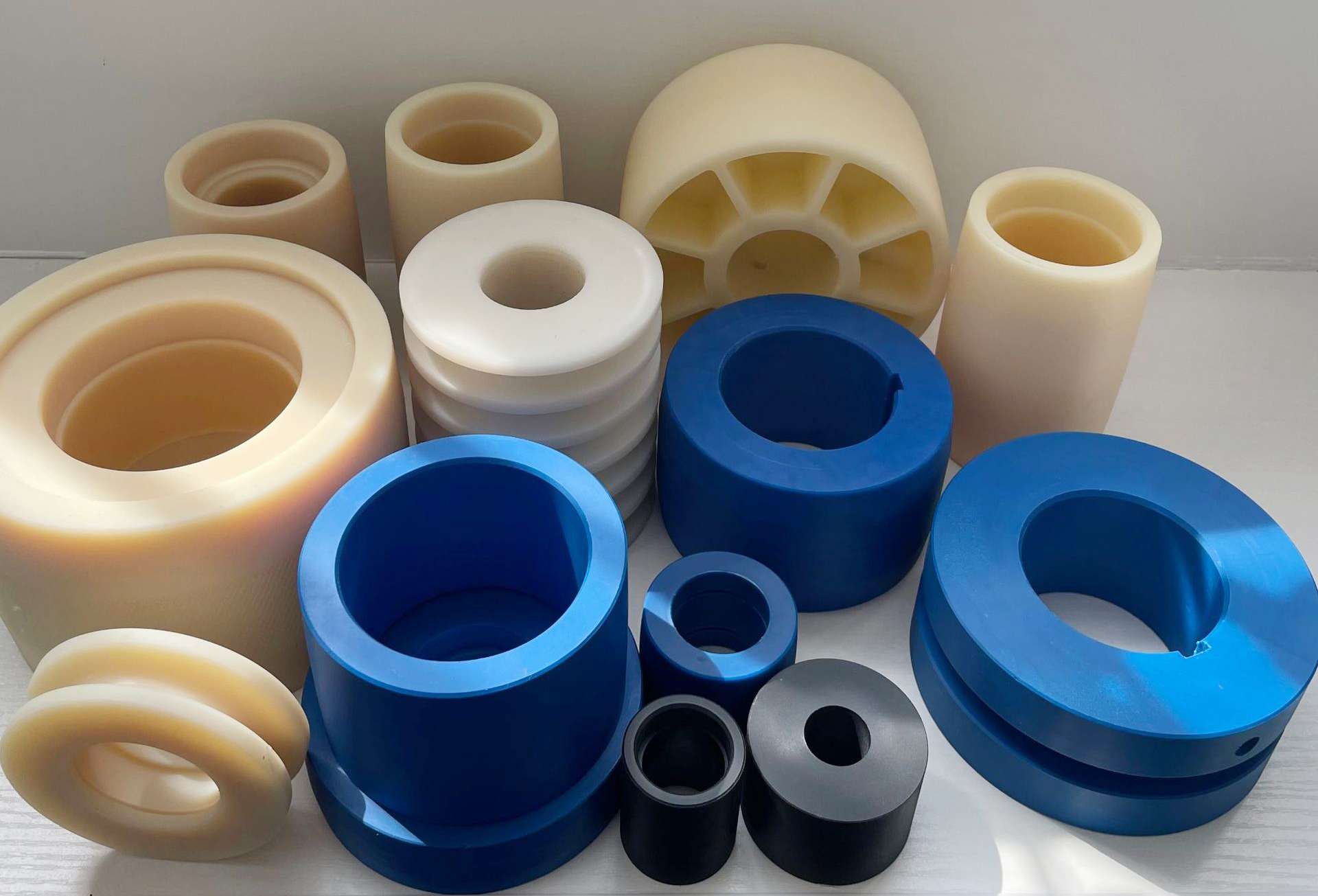

There are many methods to produce plastic parts with high precision. Modern industrial grade plastics are casted, molded, printed or machined. The first three methods are highly suitable for manufacturing complex geometrical shapes with excellent surface smoothness.

However, when you need to achieve strict tolerances or a mirror-like surface smoothness on practically any type of part, nothing beats machining for that. About 80% of plastic parts are machined via CNC milling which is the most widespread method for producing parts without rotational axes. All the rest are usually put on a lathe to get excellent surface smoothness, a machined part can be polished or chemically treated.

CNC-machined plastic materials offer a wide range of benefits compared to metal parts, such as being lightweight and corrosion-resistant. CNC-machined plastic parts are also cost effective because of the much lower cost of manufacturing them compared to metal parts. At ENERGETIC, CNC machines are in place, providing services that include milling, turning, drilling, sanding, grinding, punching, tools, and welding. We have the capability to manufacture high-performance plastic parts in sheets, rods, and other materials.

ENERGETIC can provide custom CNC plastic materials for hundreds of applications:

- General Plastic Material: HDPE, PP, ABS, PVC, PET

- Engineering Plastic Material: POM, PTFE, PA6, PA66, PC, UHMWPE, PVDF

- High Performance Plastic Material: PEEK, PPS, PEI, PAI

- Insulation Materials: Phenolic/Bakelite, 3240/FR4 Epoxy sheets & rods, Glassfiber reinforced material and so on…

Contact: Eva Jiang

Phone: +86 189 3326 4608

Tel: +86-755-89664362

Email: sales@energetic-industry.com

Add: No.601-11, Anbo Technology Baolong Industrial Zone, Baolong 4th Road, Longgang District, Shenzhen, China