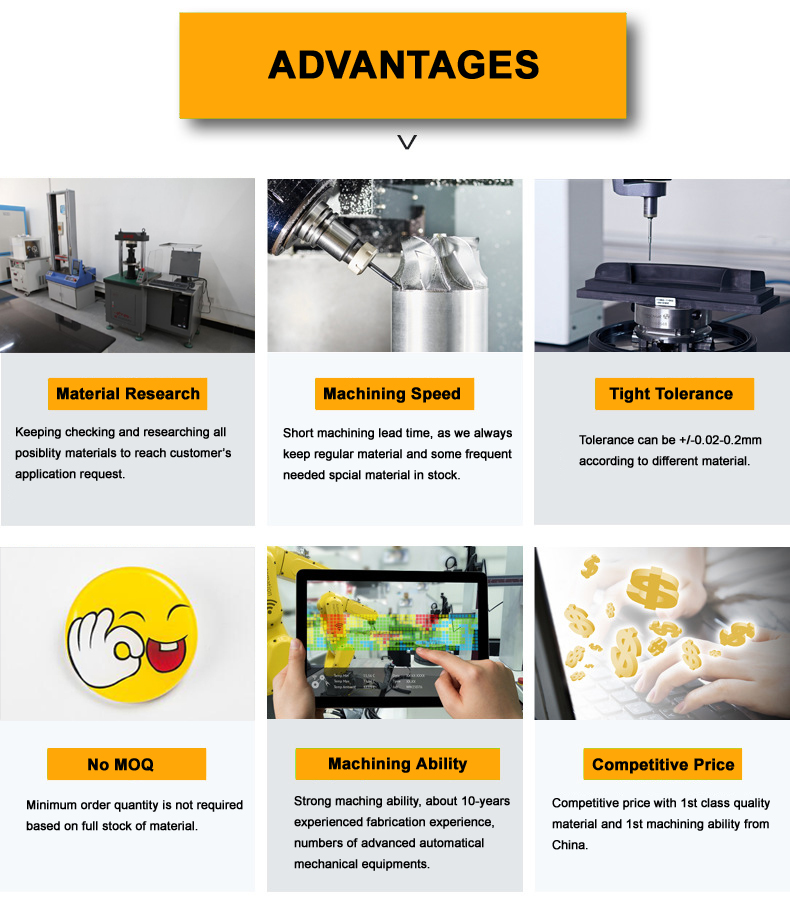

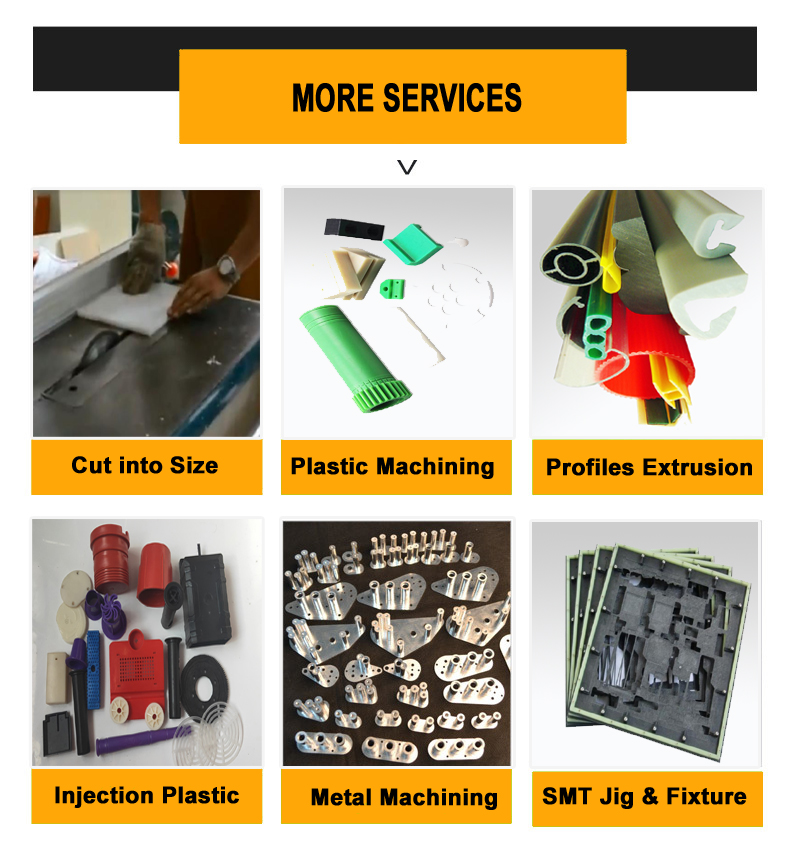

ENERGETIC Industry can custom plastic fabrication parts based on your idea, not only based on for material choosing, but also property requirements custom.

Tolerance: +/-0.2mm for plastic, 0.05mm~0.1mm for metal

- Drawing format : CAD / PDF/ DWG/ IGS/ STEP

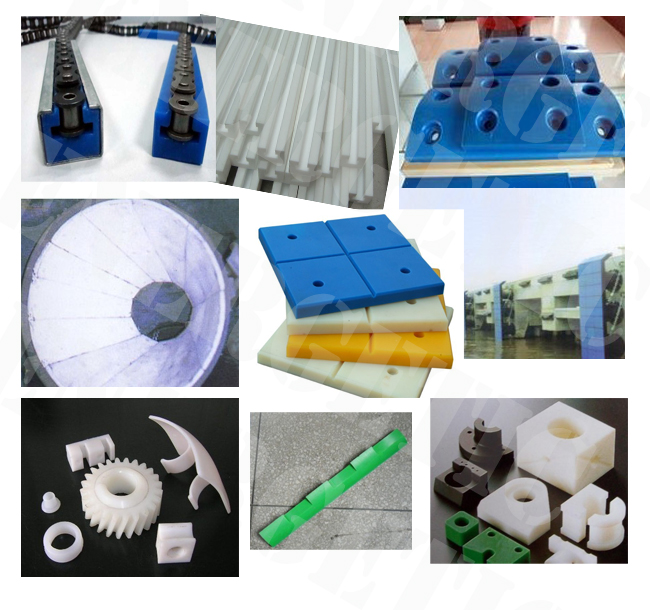

UHMW Custom Plastics:

Regular UHMWPE, Conductive UHMWPE, ESD UHMWPE

About UHMWPE:

UHMWPE (also known as Ultra High Molecular Weight Polyethylene) Sheet and Rod products are manufactured from the semi-crystalline polyethylene (PE) family. Chinese UHMWPE Sheet and rods’ maximum molecular weight can reach to 5 million which has a positive impact on material performance in an abrasive environment.

UHMWPE Advantages:

UHMWPE properties ensure that this plastic material is very light, extremely tough, chemically resistant and has excellent wear resistance.

Key Features:

▪ Excellent sliding properties

▪ High wear resistance

▪ High impact strength

▪ Very good chemical and corrosion resistance

▪ Good noise absorption

▪ Anti-adhesive

▪ High energy absorption capacity and high stress rates

▪ Temperature resistance from -200°C to +80°C

▪ Physiologically safe

Applications:

▪ Edge binding

▪ U type flame

▪ Triangular guide channel

▪ T slot

▪ Chain guide rail

▪ Wear strip

▪ Sliding guides for conveyor

Welcome to send us inquiry with idea, drawing and quantity to sales@energetic-industry.com, we are happy to hear from you.

Contact: Eva Jiang

Phone: +86 189 3326 4608

Tel: +86-755-89664362

Email: sales@energetic-industry.com

Add: No.601-11, Anbo Technology Baolong Industrial Zone, Baolong 4th Road, Longgang District, Shenzhen, China